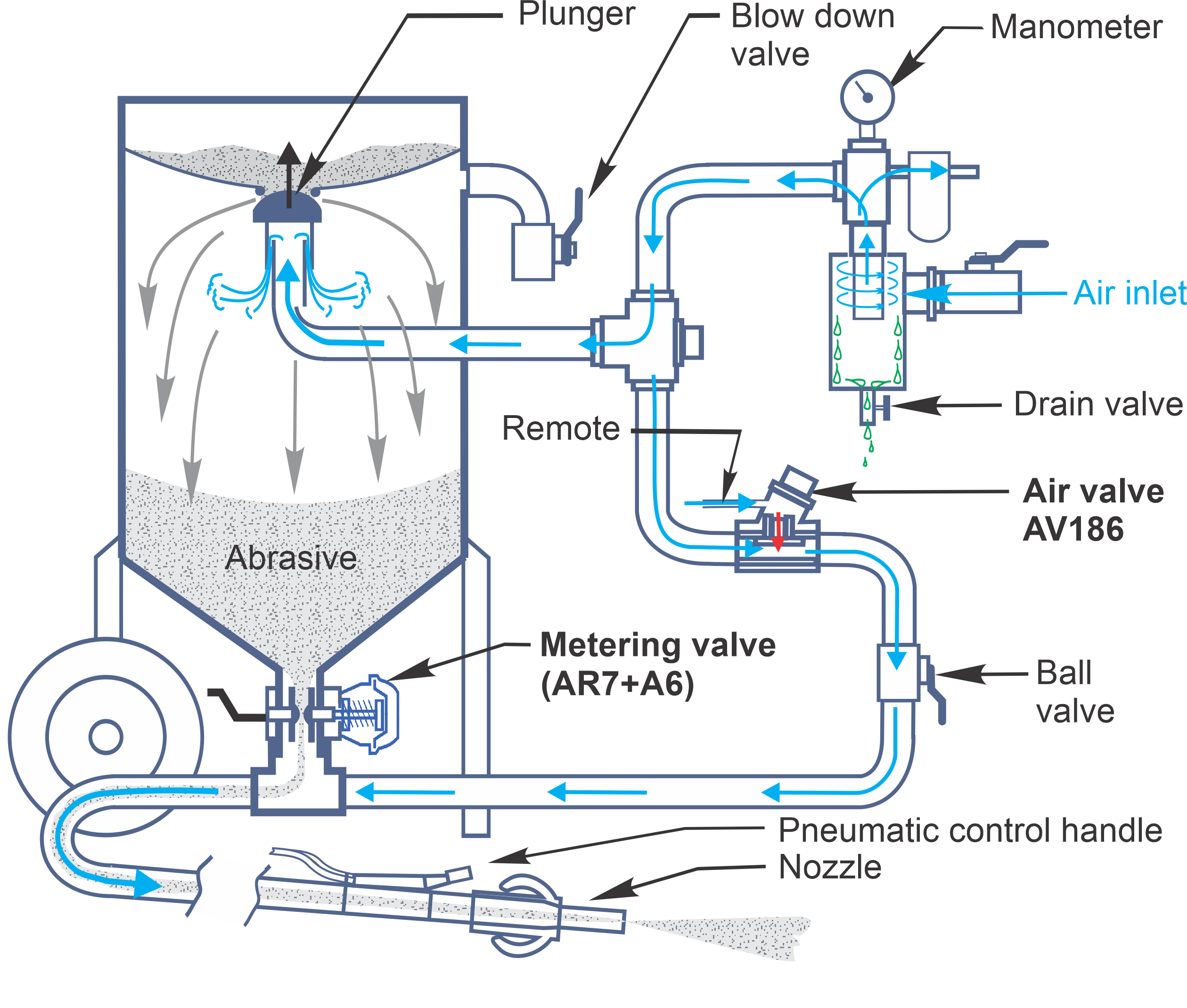

Sand Blasting Machine Process . For the most part, they operate. what is the sandblasting process? Also known as abrasive blasting, sandblasting is a surface finishing process that uses an industrial spray gun to propel abrasive particles at a very high velocity against a chosen surface. sandblasting equipment encompasses systems or machinery, along with components for projecting blast media. sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. The sandblaster has two main components: the sandblasting process works by propelling sandblasting media to a surface through the use of a sandblaster. The blast pot holds the abrasive blasting media and funnels the particles through a valve. abrasive grit blasting (also commonly known as abrasive blasting or sandblasting) involves forcibly propelling an abrasive. The blast pot and the air intake.

from istsurface.com

the sandblasting process works by propelling sandblasting media to a surface through the use of a sandblaster. abrasive grit blasting (also commonly known as abrasive blasting or sandblasting) involves forcibly propelling an abrasive. The sandblaster has two main components: sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. what is the sandblasting process? Also known as abrasive blasting, sandblasting is a surface finishing process that uses an industrial spray gun to propel abrasive particles at a very high velocity against a chosen surface. sandblasting equipment encompasses systems or machinery, along with components for projecting blast media. The blast pot and the air intake. The blast pot holds the abrasive blasting media and funnels the particles through a valve. For the most part, they operate.

How to choose a pressure sandblaster system? IST International

Sand Blasting Machine Process abrasive grit blasting (also commonly known as abrasive blasting or sandblasting) involves forcibly propelling an abrasive. Also known as abrasive blasting, sandblasting is a surface finishing process that uses an industrial spray gun to propel abrasive particles at a very high velocity against a chosen surface. the sandblasting process works by propelling sandblasting media to a surface through the use of a sandblaster. what is the sandblasting process? The blast pot holds the abrasive blasting media and funnels the particles through a valve. For the most part, they operate. abrasive grit blasting (also commonly known as abrasive blasting or sandblasting) involves forcibly propelling an abrasive. sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. The sandblaster has two main components: sandblasting equipment encompasses systems or machinery, along with components for projecting blast media. The blast pot and the air intake.

From www.newsorator.com

What Is Sandblasting? Overview] Sand Blasting Machine Process The blast pot and the air intake. the sandblasting process works by propelling sandblasting media to a surface through the use of a sandblaster. The blast pot holds the abrasive blasting media and funnels the particles through a valve. sandblasting equipment encompasses systems or machinery, along with components for projecting blast media. abrasive grit blasting (also commonly. Sand Blasting Machine Process.

From dxoflcbcx.blob.core.windows.net

Sand Blasting Oxford at Jamie Martin blog Sand Blasting Machine Process The blast pot holds the abrasive blasting media and funnels the particles through a valve. For the most part, they operate. sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. the sandblasting process works by propelling sandblasting media to a surface through the use of a sandblaster. what. Sand Blasting Machine Process.

From www.iqsdirectory.com

Sandblasting Machinery What Is It? How Does It Work? Types Sand Blasting Machine Process The blast pot and the air intake. what is the sandblasting process? The blast pot holds the abrasive blasting media and funnels the particles through a valve. sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. Also known as abrasive blasting, sandblasting is a surface finishing process that uses. Sand Blasting Machine Process.

From istsurface.com

Automated Sandblasting Systems IST International Surface Technologies Sand Blasting Machine Process The blast pot and the air intake. the sandblasting process works by propelling sandblasting media to a surface through the use of a sandblaster. sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. The sandblaster has two main components: sandblasting equipment encompasses systems or machinery, along with components. Sand Blasting Machine Process.

From exopsycyo.blob.core.windows.net

Sandblasting Media Guide at Victor Nagle blog Sand Blasting Machine Process Also known as abrasive blasting, sandblasting is a surface finishing process that uses an industrial spray gun to propel abrasive particles at a very high velocity against a chosen surface. sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. the sandblasting process works by propelling sandblasting media to a. Sand Blasting Machine Process.

From www.powertoolslive.com

How Does Direct Pressure Pot Sandblaster Work? IST Surface Sand Blasting Machine Process The blast pot and the air intake. The blast pot holds the abrasive blasting media and funnels the particles through a valve. sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. what is the sandblasting process? sandblasting equipment encompasses systems or machinery, along with components for projecting blast. Sand Blasting Machine Process.

From orlandosandblastingpros.com

Sandblasting Orlando Media, Dustless, Mobile Blasting Sand Blasting Machine Process The blast pot and the air intake. sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. The blast pot holds the abrasive blasting media and funnels the particles through a valve. abrasive grit blasting (also commonly known as abrasive blasting or sandblasting) involves forcibly propelling an abrasive. Also known. Sand Blasting Machine Process.

From www.iqsdirectory.com

Abrasive Blast Equipment What Is It? How Does It Work? Uses Sand Blasting Machine Process abrasive grit blasting (also commonly known as abrasive blasting or sandblasting) involves forcibly propelling an abrasive. sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. sandblasting equipment encompasses systems or machinery, along with components for projecting blast media. the sandblasting process works by propelling sandblasting media to. Sand Blasting Machine Process.

From www.youtube.com

Sandblasting Process Introduction, Materials& their Uses YouTube Sand Blasting Machine Process sandblasting equipment encompasses systems or machinery, along with components for projecting blast media. The blast pot holds the abrasive blasting media and funnels the particles through a valve. what is the sandblasting process? The blast pot and the air intake. For the most part, they operate. the sandblasting process works by propelling sandblasting media to a surface. Sand Blasting Machine Process.

From hydroteckengineering.com

Sand Blasting Machine Hydroteck Engineering Company Sand Blasting Machine Process sandblasting equipment encompasses systems or machinery, along with components for projecting blast media. sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. Also known as abrasive blasting, sandblasting is a surface finishing process that uses an industrial spray gun to propel abrasive particles at a very high velocity against. Sand Blasting Machine Process.

From exopczlwm.blob.core.windows.net

Sandblasting Explained at Irene Jones blog Sand Blasting Machine Process sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. what is the sandblasting process? Also known as abrasive blasting, sandblasting is a surface finishing process that uses an industrial spray gun to propel abrasive particles at a very high velocity against a chosen surface. The blast pot and the. Sand Blasting Machine Process.

From www.iqsdirectory.com

Sandblasting Machinery What Is It? How Does It Work? Types Sand Blasting Machine Process sandblasting equipment encompasses systems or machinery, along with components for projecting blast media. abrasive grit blasting (also commonly known as abrasive blasting or sandblasting) involves forcibly propelling an abrasive. For the most part, they operate. what is the sandblasting process? The blast pot holds the abrasive blasting media and funnels the particles through a valve. the. Sand Blasting Machine Process.

From www.iqsdirectory.com

Sandblasting Machinery What Is It? How Does It Work? Types Sand Blasting Machine Process Also known as abrasive blasting, sandblasting is a surface finishing process that uses an industrial spray gun to propel abrasive particles at a very high velocity against a chosen surface. sandblasting equipment encompasses systems or machinery, along with components for projecting blast media. The blast pot holds the abrasive blasting media and funnels the particles through a valve. . Sand Blasting Machine Process.

From www.iqsdirectory.com

Sandblasting Machinery What Is It? How Does It Work? Types Sand Blasting Machine Process what is the sandblasting process? The sandblaster has two main components: For the most part, they operate. The blast pot holds the abrasive blasting media and funnels the particles through a valve. The blast pot and the air intake. Also known as abrasive blasting, sandblasting is a surface finishing process that uses an industrial spray gun to propel abrasive. Sand Blasting Machine Process.

From istsurface.com

ECO 420 Sandblast for LightDuty Applications ISTblast Sand Blasting Machine Process sandblasting equipment encompasses systems or machinery, along with components for projecting blast media. what is the sandblasting process? sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. The blast pot and the air intake. The sandblaster has two main components: For the most part, they operate. the. Sand Blasting Machine Process.

From engineeringlearn.com

Working of Automatic Sand Blasting Machine Archives Engineering Learn Sand Blasting Machine Process Also known as abrasive blasting, sandblasting is a surface finishing process that uses an industrial spray gun to propel abrasive particles at a very high velocity against a chosen surface. the sandblasting process works by propelling sandblasting media to a surface through the use of a sandblaster. what is the sandblasting process? For the most part, they operate.. Sand Blasting Machine Process.

From istsurface.com

How to choose a pressure sandblaster system? IST International Sand Blasting Machine Process The blast pot and the air intake. what is the sandblasting process? The sandblaster has two main components: The blast pot holds the abrasive blasting media and funnels the particles through a valve. For the most part, they operate. sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. . Sand Blasting Machine Process.

From dxoibuhfd.blob.core.windows.net

Sand Blasting Machine Working at Bessie Scofield blog Sand Blasting Machine Process sandblasting is the process of propelling fine, abrasive materials at high velocities to achieve a number of results. the sandblasting process works by propelling sandblasting media to a surface through the use of a sandblaster. abrasive grit blasting (also commonly known as abrasive blasting or sandblasting) involves forcibly propelling an abrasive. The blast pot holds the abrasive. Sand Blasting Machine Process.